The SPbGASU Department of Land Transport and Technological Machines conducts research into improving the design of municipal vehicles, in particular, snow removal equipment for city highways.

Today, the capacity of Russian roads is significantly reduced in winter: after heavy snowfalls, the passage of snowplows creates snow banks along the roads, taking up to half the highway lane. While these machines are quick to clear the roadway of snow, clearing the shovels takes a long time.

At the same time, municipal companies lack standard snow removal equipment— claw loaders —for city highways. Front-end loaders, used additionally during heavy snowfalls, mitigate the problem, but they block at least two traffic lanes when loading snow onto vehicles. It's worth noting that front-end loaders are the most common type of specialized equipment used by road and construction companies, and they are rarely used for construction work in winter.

An obvious technical solution for improving snow removal from urban roads is to equip front-end loaders with a rear-dumping function. This allows the loader to load snow into a dump truck while remaining in the same lane.

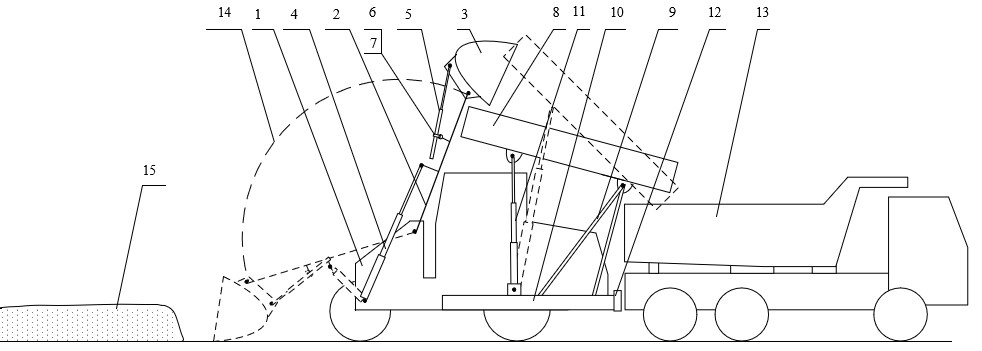

Fig. 1 shows a diagram of the proposed design of a front loader with rear bucket discharge.

Fig. 1 Proposed design of a front loader with rear bucket discharge

Fig. 1 Proposed design of a front loader with rear bucket discharge

The loader consists of:

– a base machine 1,

– a double-beam boom 2, the lower part of which is pivotally fixed in the front part of the base machine,

– a bucket 3, pivotally fixed on the upper part of the boom 2,

– a telescopic boom lifting hydraulic cylinder 4, pivotally fixed between the boom beams on the front part of the base machine frame,

– a bucket turning hydraulic cylinder 5, installed by means of a clamp 6 on a bracket 7, fixed on a crossbar connecting the boom beams in their upper part,

– a metal chute 8, installed above the cabin and the engine by means of a pair of two-legged stands 9, fixedly mounted on the sides of the front part of the frame 10,

– and two hydraulic cylinders 11, pivotally fixed on the sides of the middle part of the frame 10, a damping device 12, fixed on the front part of the frame 10 at a height from the road surface corresponding to the height of the bumper of the dump truck 13..

The hydraulic cylinder 5 for turning the bucket 3 is pivotally secured in its middle part to the boom 2 by means of a clamp 6.

Chute 8 is pivotally attached to stands 9 and rods of the hydraulic cylinder 11. The right end of chute 8 extends beyond the base vehicle by one to one and a half meters, and its height should be at least half a meter higher than the top edge of dump truck 13 used for hauling snow, i.e., 3.2 m. Number 14 shows the trajectory of the boom end. Number 15 shows the shaft of snow being removed.

The proposed front loader operates as follows.

- Before collecting snow from windrow 15, located along the right edge of the roadway, loader 1 lowers bucket 3 to the lower position (shown by the dotted line) by retracting hydraulic cylinder 4.

- Dump truck 11 approaches the loader from the rear of chute 6.

- Chute 6 is lowered by retracting cylinder 9 .

- Bucket 3 is filled with snow by moving loader 1 to the left. Once full, the bucket is rotated clockwise using cylinder 5 until the open end of the bucket is horizontal.

- Boom 2 is then raised using cylinder 4 until bucket 3 is above the left edge of chute 8. While boom 2 is raised, the open end of the bucket is maintained in a horizontal position using cylinder 5.

- Once bucket 3 is above chute 8, it is rotated clockwise using cylinder 5 to discharge snow into the chute. While the bucket is being raised, the dump truck drives close to the loader until its rear bumper touches damper 12.

- The bucket is then lowered to the snow collection position. One to two seconds after cylinder 4 is activated to lower the boom, cylinders 11 are activated to raise the left side of chute 8 to the top position (shown by the dotted line), ensuring that snow slides from chute 8 into the dump truck body 13. Once the loader begins moving to collect snow with the bucket, the chute is lowered.

The cycle of picking up and unloading snow is repeated three to five times until the body of the dump truck 13 is full.

For the convenience of the dump truck driver, the damping device 12 can be equipped with sound and light signaling sensors.

Computer modeling has shown that the new loader's productivity is three times higher than that of a claw loader and one and a half times higher than that of a typical front-end loader.

A utility model application has been filed for the design of the new loader.

The development was carried out as part of research projects by the research and teaching staff of SPbGASU using internal grants in 2025.