SPbGASU has completed an important stage of research dedicated to the development of a new generation of suspensions for transportation and construction machinery.

The study was conducted by Roman Litvin, PhD, Associate Professor at the Department of Land Transport and Technological Machines and Deputy Dean for Research at the Faculty of Automobile and Road Building. The work has been conducted as part of the 2025 grant competition for university faculty members.

Modern transportation and construction vehicles operate in conditions that place high demands on suspension reliability. Traditional hydraulic shock absorbers are prone to leaks, are temperature-sensitive, and require low-temperature operation, which is especially critical for operations in the Far North.

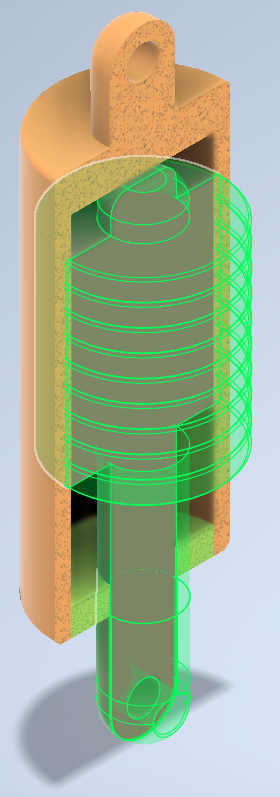

As an alternative, a liquid-free magnetic shock absorber (LFMA) has been proposed, in which damping is achieved through the interaction of magnetic fields and eddy currents. This system can combine the functions of a spring and a shock absorber, eliminating the need for liquid working fluids.

"We aimed to create a system that not only solves classic suspension problems but also allows us to move forward—towards compact, reliable, and adaptive solutions. The liquid-free magnetic shock absorber combines the functions of both elastic and damping elements, simplifying the design and opening up opportunities for scalability," noted Roman Litvin.

A nonlinear mathematical model of suspension dynamics was developed, linearized, and a proportional-differential (PD) control law using a Hall effect sensor was proposed. This allowed to formulate analytical expressions for calculating stiffness, damping, and heat loss.

The key findings of the studies are presented in the table.

|

Object of study |

Equivalent stiffness, N/m |

Damping coefficient, N·s/m |

Heat loss, W |

|

Operator's seat |

8883 |

565 |

5,7 |

|

Light-duty car (wheel) |

17 913 |

1451 |

14,5 |

|

KAMAZ-6520 (wheel) |

176 409 |

15 598 |

156,0 |

The analysis showed:

- as mass and loads increase, the requirements for magnetic induction, control current, and heat dissipation increase sharply;

- for small and medium-sized systems, the parameters are within the range achievable with permanent magnets and compact coils;

- for heavy equipment, modular multi-channel designs are required to avoid overheating and saturation of the magnetic circuit.

The development opens up prospects for the implementation of LFMA in a wide range of areas:

- light-duty vehicles – for increased comfort and safety;

- construction and road transport equipment – for reliable operation in harsh conditions;

- robotics, where lightweight construction and temperature independence are important.

"We're essentially creating a platform technology. If implemented correctly, the LFMA can replace two suspension components at once, reducing weight and increasing the design's reliability," emphasizes Roman Litvin.

The study's results are generating interest among industrial partners. Specifically, the possibility of collaboration with the St Petersburg Tractor Plant (part of the Kirov Plant) and several leading construction and road transport engineering companies is being discussed. Such developments could form the basis for the creation of prototypes of new suspensions, and subsequently, for their introduction into serial production. International cooperation is also a promising area, as adaptive and energy-efficient suspensions are in demand worldwide.

Research conducted at SPbGASU confirms the feasibility of transitioning from traditional hydraulic solutions to new adaptive suspension systems that are resistant to temperature and operational loads.

The project was supported by a grant from SPbGASU and reflects the university's strategic focus on developing innovative technologies in transport engineering, as well as strengthening ties with industrial enterprises and international research centers.

.jpg)

.jpg)